(Click on logo for company web site)

Sonderausstattungen

90° Einlaufsystem

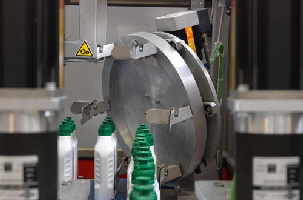

Um das Drehen und Ausrichten von Produkten zu vereinfachen hat Baumer das patentierte 90° Zuführsystem für ein breites Spektrum an Produkten konstruiert, das zudem mit einer geringer Aufstellungsfläche auskommt. Dieses spezielle System ermöglicht eine kontinuierliche Zuführung durch einen rotierenden Abschiebemechanismus, der die Produkte ohne Staudruck mit gleichmäßiger Geschwindigkeit zuführt.

Um das Drehen und Ausrichten von Produkten zu vereinfachen hat Baumer das patentierte 90° Zuführsystem für ein breites Spektrum an Produkten konstruiert, das zudem mit einer geringer Aufstellungsfläche auskommt. Dieses spezielle System ermöglicht eine kontinuierliche Zuführung durch einen rotierenden Abschiebemechanismus, der die Produkte ohne Staudruck mit gleichmäßiger Geschwindigkeit zuführt.

Die Hauptmerkmale des Patents decken die Möglichkeit ab rechteckige, ovale und/oder geformte Behälter, zum Teil auch nur eingeschränkt stabile Behälter zu verarbeiten, ohne einen aufwendigen Linienverteiler zum Verteilen der Produkte zu benötigen, wodurch diese Zuführung sehr kompakt ausfällt.

Die 90° Zuführung kann mit unseren Tray- & Schrumpfpackern sowie Kartonierern kombiniert werden. Mit einer Leistung bis zu 24.000 Produkten/h eignet sie sich ebenfalls zur Zusammenfassung von 2 oder mehr Füll- Linien auf eine Verpackungsmaschine.

VORTEILE

- Sehr kompakte Maschine.

- Lombinierbar mit Tray- & Schrumpfpackern sowie Kartonierern (oder kombinierten Maschinen).

- Kontinuierliche Zuführung zum 90° Zuführsystem gesteuert mit Servomotoren.

- Hohe Produktionsleistungen möglich.

- Keine Linienverteiler zum Kanalisieren der Produkte erforderlich

Partitionen

Baumers Wrap Around Kartonierer können mit einem System zum Einsetzen von Partitionen/ Gefäche ausgestattet werden, Um den ANforderungen aller Verpackungs- und Versanstspezifikationen zu entsprechen bietet Baumer zwei Systeme für das Einsetzen der Partitionen/ Gefäche an:

Nicht- zusammengesetzte Partitionen/ Gefäche

Baumer hat ein exklusives System zum Einsetzen von nicht- zusammengesetzen Partitionen/ Gefächen von unten konstruiert und patentiert, das dem Kunden mehrere Vorteile bringt:

- Signifikante Einsparungen durch die Verwendung einfacher, flacher Kartonzuschitte statt vorgefertigter Partitionen/ Gefäche.

- Einfache und sichere Beladung des Zuschnittmagazins in niedriger Höhe.

- Produktionsleistung bis zu 65 Kartons pro Minute.

- Möglichkeit zur Veroackung von Produkt mit größeren Konfigurationen, z.B. 6x4, 4x3.

- Keine Beschädigung der Etiketten

Vorgefertigte Partitionen

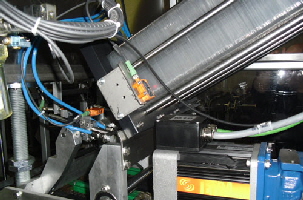

Baumer hat ein rotierendes System zum Einsetzen der Partitionen/ Gefäche konstruiert, dessen Leistung gegenüber einer Standard- Roboter- Lösung doppelt so hoch ist.

Die Partitionen/ Gefäche werden mit Saugnäpfen dem Magazin entnommen und bis zum Einsetzen zwischen den Flaschen geführt, wobei spezielles Augenmerk darauf gelegt wurde, die Etikette nicht zu beschädigen.

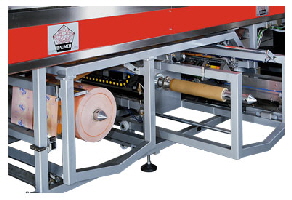

Automatischer Folienrollenwechsel

Dieses System enthält 5 internationale, als hoch innovativ eingestufte Patente. Es erlaubt die einzige Unterbrechnungsfreie Produktion und erlaubt den automatischen Wechsel der Folienrollen bei Produktionsleistung ohne Eingriff und/ oder Anwesenheit des Bedieners, und ohne die Folie zu verschweißen.

Die Haupteigenschaften dieses innovativen Systems hinsichtlich der Einsparungen in der Produktion sind unterbrechungsfreier Betrieb, außergewöhnliche Vielseitigkeit und extrem genauer Folienzuschnitt das es erlaubt bis zu 15% an Folienmaterial einzusparen

VORTEILE

- Deutliche Steigerung der Produktionseffizienz da die Maschine zum Folienrollenwechsel nicht mehr angehalten, oder die Leistung reduziert wird - dies erfolgt bei Produktionsleistung.

- Mehr als 15% Einsparung an Rohmaterial bei der Folie dank sowohl der Folienstärken- und -breitenreduzierung als auch Nutzung der Folienrolle bis zum Schluss, wodurch zudem noch Entsorgungskosten verringert werden.

- Kein Verschweißen der Folie beim Rollenwechsel.

- Nutzbar mit klarer und/ oder bedruckter Folie.

Tray mit Deckel

Baumer verfügt über ein spezielles System um die Produkte in einen Tray mit Deckel, 2- oder 4- seitig verschlossen, zu verpacken.

Baumer verfügt über ein spezielles System um die Produkte in einen Tray mit Deckel, 2- oder 4- seitig verschlossen, zu verpacken.

Diese neuartige Verpackung ermöglicht Kartoneinsparungen und bietet dem Kunden die Möglichkeit seine Produkte in verschiedenen Varianten am Verkaufspunkt zu präsentieren.

Dieser Traypacker kann auch WrapAround Kartons und mit Schrumpffolie verpacken, damit erhält der Kunde ein Maximum an Flexibilität.

VORTEILE

- Flexibilität in der Produktion und Möglichkeit maketing- gerechte Verpackung für den Einzelhandel zu erzeugen.

- Einfach zu öffnende Verpackung.

- Möglichkeit auch WrapAround Kartons und Schrumpffolie auf der selben Maschine zu verpacken.

Top Tray

Baumer hat einen Schrumpfpacker entwickelt und gefertigt, der mit einem speziellem System zum Einsetzen eines oberen Kunststoff- Trays um den Flaschenhals ausgestattet ist.

Baumer hat einen Schrumpfpacker entwickelt und gefertigt, der mit einem speziellem System zum Einsetzen eines oberen Kunststoff- Trays um den Flaschenhals ausgestattet ist.

Dieses System eignet sich für verschiedene Produkte und kann unterschiedliche Konfigurationen verarbeiten (3x2, 4x3, usw.).

Dieses System ermöglicht die Herstellung von Multipacks in zwei oder 3 Bahnen, auch ohne Verwendung von Schrumpffolie. Die selbe Maschine kann dann das Produkt in einen Tray packen oder in Folie einschlagen, um z.B. eine 24-er Pack Flaschen mit 4-er Multipacks zu erstellen.

BM Band

Das von Bumer patentierte BM BELT System ermöglicht die Produktion von verschiedenen Verpackungstypen mit nur einer Maschine (z.B. nur Folie, Tray& Folie, flache Pappe & Folie und WrapAround) mit schnellem und automatischem Formatwechsel.

Das von Bumer patentierte BM BELT System ermöglicht die Produktion von verschiedenen Verpackungstypen mit nur einer Maschine (z.B. nur Folie, Tray& Folie, flache Pappe & Folie und WrapAround) mit schnellem und automatischem Formatwechsel.

Das System verwendet einen motorisch positioniertes Transportband, welches in die Maschine integriert ist, das die Funktion hat, die Ketten die die Trayzuschnitte transportieren zu ersetzen, um so von Wrap-Around zur “nur Folien” Konfiguration in kürzester Zeit zu wechseln. Dieses Transportband wird komplett über das Bedienerpaneel gesteuert und während des Formatwechsels automatisch positioniert, ohne das der Bediener eingreifen muß.

Durch dieses System werden Baumer Maschinen noch flexibler und bieten dem Kunden bisher nicht verfügbarer Verpackungsvarianten auf einer Maschine mit schnellem Formatwechsel

VORTEILE

- Flexibilität an verschiedenen Verpackungstypen.

- Komplett automatisches System zum Wechsel von “nur Folie” zu WrapAround Karton oder Tray & Folie in kurzer Zeit.

- Möglichkeit zum Verpacken von losen Produkten und Multipacks.

Stapler

Baumer verfügt verschiedene Typen an Stapelvorrichtungen entsprechend des zu verpackenden Produkts.

Baumer verfügt verschiedene Typen an Stapelvorrichtungen entsprechend des zu verpackenden Produkts.

- Stapler für lose Produkte (Becher auf Becher)

- Stapler für Trays

- Stapler für flasche Pappen (Pads)

Das Staplersystem arbeitet unterbrechungsfrei ohne den Produktfluss zu stoppen, wodurch hohe Produktionsleistungen und höhrere Zuverlässigkeit gewährleistet werden

Durch das Stapeln der Produkte kann die Produktionsleistung verdoppelt werden (Produkte/h) ohne die Taktzahl der anschließenden Palettierung zu vergrößern.

Traypacker für Displays

Baumer hat eine spezielle Traypackerserie, den Traypacker 1000 entwickelt. Die Maschine kann die üblichen Formate oder Quincunx (versetzte, flächenoptimierte Formate) für höhere Produktdichte in Trays packen.

Diese Maschine wurde entwickelt um große Trays herzustellen, wie:

- ½ Industriepalette (1000x600 mm)

- ½ Europalette (800x600 mm)

- ¼ Europalette (600x400 mm)

Der Traypacker 1000 bietet viele Vorteile:

Hohe Zuverlässigkeit

Der Verpackungsprozeß gewährleistet die Produktstabilität: Flaschen werden mit konstanter Geschwindigkeit dem Gruppierungsbereich zugeführt. Dann werden sie auf von unten zugeführte Trays gepackt, und während des kontinuierlichen Durchlaufs auf allen 4 Steiten um das Produkt verschlossen

Kompakte Abmessungen:

Die kompakten Abmessungen der Maschine vereinfachen die Integration und den erforderlichen Platzbedarf.

Innovatives Display- System:

Trays können am Verkaufspunkt direkt von der Palette angeboten werden, ohne großes Umpacken, schnell und einfach. Dieser Verpackungstyp ermöglicht es sowohl dem Verkäufer beim Aufbau der Produkte als auch dem Kunden bei der Auswahl der Produkte höhere Flexibilität.

Gerne stehen wir Ihnen für Ihre Anfragen und für persönliche Beratungsgespräche in Ihrem Haus zur Verfügung.